doks.inventairy

The innovative drone-based solution for automated stocktaking in high-bay!

With doks.inventairy, problems in inventory management are a thing of the past. The fully automated system gathers, processes and visualizes inventory data in high-bay warehouses precisely and in real-time.

Our solution at a glance:

- Fully automated system for inventory data collection and stocktaking

- Can be used in all indoor racking warehouses

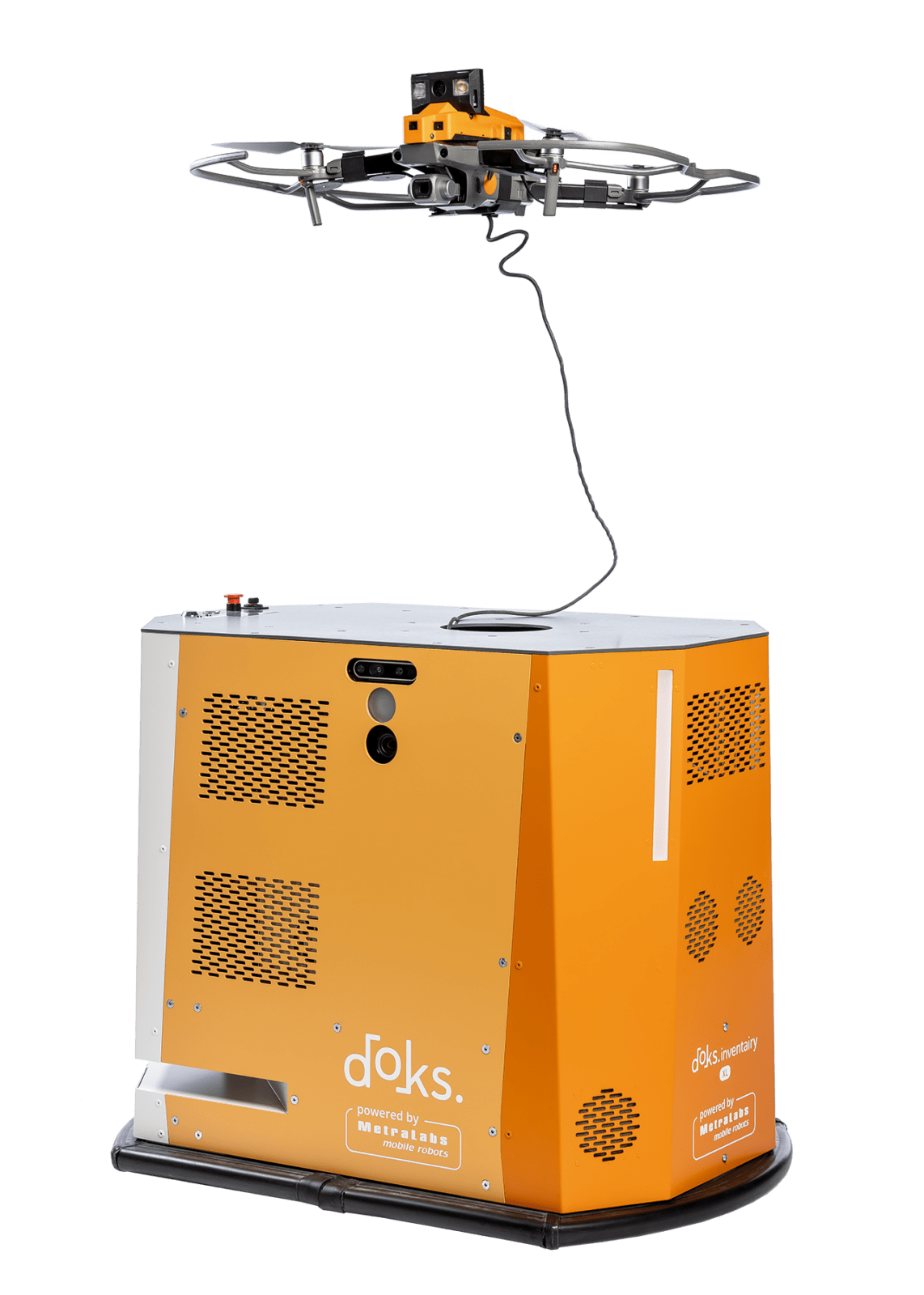

- Combination of ground vehicle and drone

- No operator or supervisor required

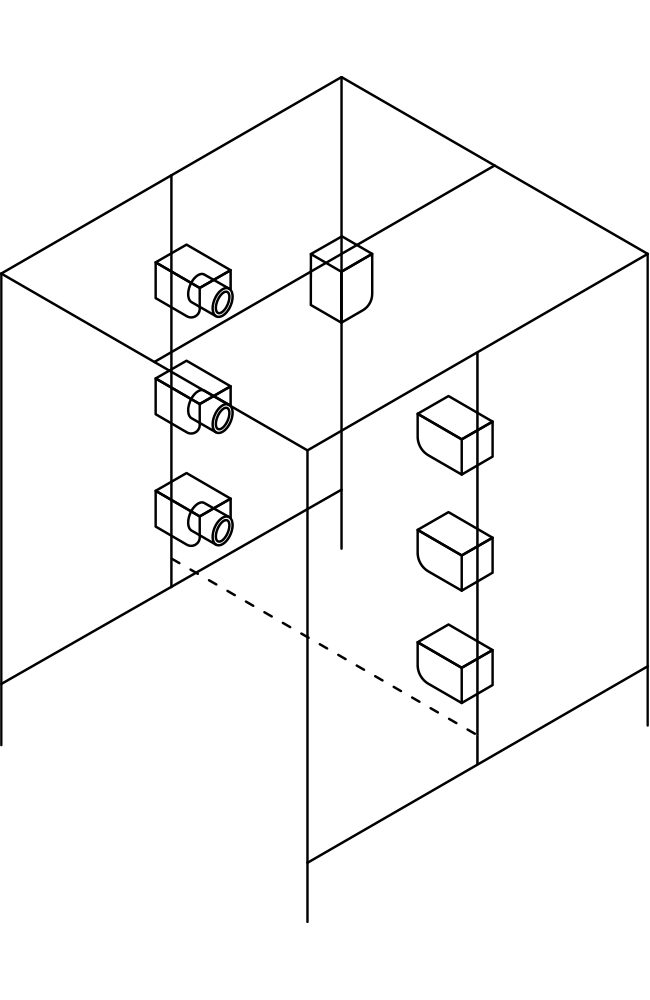

- Powerful sensor technology for machine reading of labels and photo documentation

- Inventory lists and digital twin of each shelf

- Retrieval of inventory results via digital user interface

- Comparison UI for target/actual comparison

- Interfaces for data exchange with all common WMS and ERP

- Data collection on demand at the push of a button or conveniently scheduled in advance

- Night flight mode for use in darkness

Barcode and QR code recognition and matching

Fully autonomous operation around the clock

5 hours of uninterrupted flight

> 99% data quality

Integration with minimal effort

Reduction of cost and time

This is how doks.inventairy works:

- One-time system setup and integration into the warehouse within a few hours

- One-time installation of the docking station and IT integration

- Data recording is started via the digital user interface or terminated in advance

- doks.inventairy starts from the docking station to the starting point of the mission

- Automated data taking is started

- All relevant rows of shelves and parking spaces are flown to

- Barcode scanners capture every label

- Cameras create images of each detected object

- Live data processing during the flight in the digital user interface

- Inventory lists and digital shelf replicas can be shown up on the user interface

- Export to existing WM and ERP systems

- doks.inventairy returns to the docking station and waits for the next mission

Fully automated system for inventory data collection and inventory 24/7.

One solution - many advantages:

- Complete substitution of manual stocktaking and search processes

- Can be used flexibly in terms of time - even at night and on weekends

- Simple and fast integration into existing warehouses and IT structures

- Significant increase in data quality to over 99 %

- Maximum up-to-dateness through continuous inventory checks

- Maximum transparency in quantities and positions of stored objects

- Significant time savings compared to manual data entry

- Noticeable reduction of inventory-based costs due to lower personnel deployment

- Relief of warehouse staff for value-adding activities

- Immediate identification of bottlenecks and shortages

- No additional infrastructure required - can be seamlessly integrated into existing warehouses

doks.inventairy – Fully automated inventories in high-bay warehouses

Meter-high rows of racks, tens of thousands of storage locations and constantly increasing throughput volumes. Recording up-to-date and reliable inventory information in high-bay warehouses is no child’s play – especially if you have to resort to time-consuming and inefficient manual methods. Counting and documentation errors in manual inventory processes, faulty scanning processes during storage and retrieval, or the mix-up of pallets or storage locations are not uncommon. Reasons for deviations between target and actual inventory can be found in almost all manually performed warehouse processes. And this can have serious consequences for the entire supply chain: bottlenecks and shortages of critical parts that are detected too late, pallets that customers are urgently waiting for that are not found, or permanently unused capacities not only result in high costs, but can also jeopardize the competitiveness of companies in the long term.

With the use of our doks.inventairy solution, inventory management problems are a thing of the past. The fully automated system records, processes and visualizes inventory data in the high-bay warehouse with high precision and in real time. Technically, this is made possible by the interaction of an autonomously operating ground vehicle and a flying drone, which are connected by a cable. During data acquisition, the system flies to each storage location in the warehouse and records the occupancy of the respective location by automatically reading the labels attached to the stored objects with the help of the integrated barcode scanners. Thanks to the cameras installed in the ground vehicle and the drone, the system also provides high-resolution photos of each storage location recorded. Even empty shelf locations are detected and localized by the system. Best of all, thanks to the system’s complete autonomy and integrated night flight feature, doks.inventairy can be used flexibly and around the clock. Stocktaking at the push of a button, independent of warehouse closing times, holidays and employee availability.

In order to obtain maximum added value from the collected inventory data, it is already intelligently processed during use and prepared and visualized in our digital user interface – and, if desired, also imported directly into existing WM and ERP systems. In addition to a classic inventory list showing the quantities available in the warehouse, doks.inventairy also provides a digital image of each individual shelf. This provides users with insightful information about the entire warehouse structure and a digital twin of their warehouse. Where is each object located? In which shelves are there still free spaces? What do the stored pallets look like? These and many other questions can be answered with a glance at the automatically recorded inventory results. Or in other words – with the use of doks.inventairy, stocktaking and inventory in high-bay warehouses becomes child’s play.