doks.gate

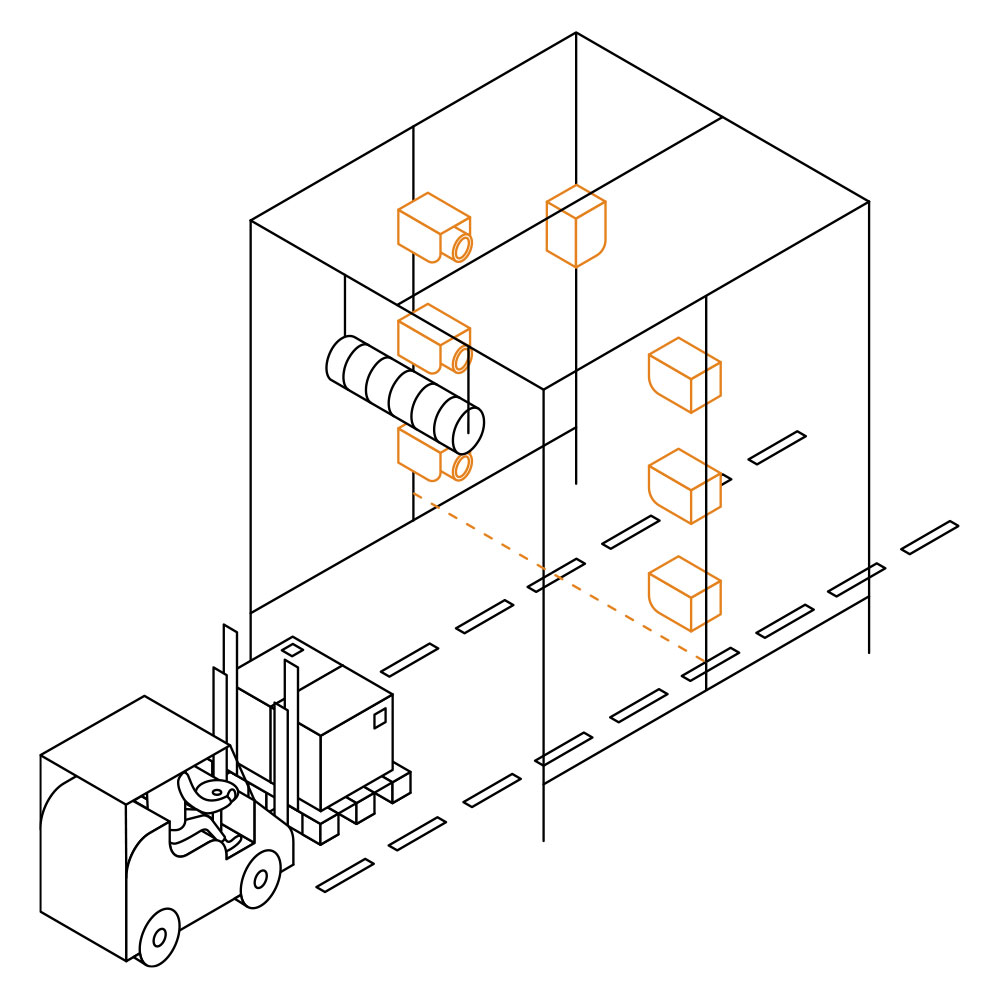

Automatic scanning and documenting in passing during loading and unloading.

With our doks.gate solution, scanning and documentation processes in inbound and outbound areas can be fully automated.

Our solution at a glance:

- Fully automated system for recording and documenting intralogistic material movements

- No operator required - can be seamlessly integrated into existing structures

- Applicable in all intralogistic areas

- Customized hardware and software components

- Data acquisition via cameras and, if necessary, additional sensors

- Retrieval of results via digital user interface

- Seamless integration into existing processes and structures

- Data-side linking with WMS and ERP

Retrieve master data and scan labels

Preservation of evidence through photographs

Time & cost savings of up to 90% time and cost

Preparation for storage and shipping

Link between inbound & outbound

Data-side linking with WMS and ERP

This is how doks.gate works:

- Installation on site

- One-time software set-up and customizing

- Data acquisition is triggered fully automated via light barriers

- Cameras and, if necessary, other sensors record every material movement

- Intelligent software components generate relevant information from the image data

- Calculation of throughput quantities and times

- Creation of high-resolution photo documentation from different perspectives

- Acquisition of further master data such as dimensions, temperature or volume

- Provision of all data records in real time via digital user interface

- Export to existing IT and warehouse management systems

Customized hardware and software components - suitable for use in all intralogistics areas.

One solution - many advantages:

- Complete substitution of manual scanning and documentation operations

- Fully automated system - without manual intervention

- Maximum timeliness - live data processing and immediate export

- Maximum transparency in throughput quantities and times

- Significant acceleration of intralogistic transport processes

- Noticeable increase in efficiency for warehouse employees

- Extensive documentation of damages and qualitative factors for transparent communication and traceability

- No additional infrastructure required - can be seamlessly integrated into existing transport processes

doks.gate - scanning and documenting in passing

Manual scanning processes cost time and slow down warehouse employees in their actual activities. If, in addition, qualitative factors, such as the condition of a pallet ready for shipping, also have to be documented manually, this often means a considerable delay in transport and storage processes.

With our doks.gate solution, scanning and documentation processes in inbound and outbound areas can be fully automated. Users gain maximum transparency in all material movements, know the exact throughput quantities and times, and have access to precise and complete photo documentation for every transport. doks.gate can be seamlessly integrated into existing structures and requires no manual intervention. By substituting manual scans, intralogistics processes can be accelerated noticeably and warehouse employees can perform their tasks much more efficiently.

The recipe for success of the gates lies in the intelligent interaction of hardware and software components individually adapted to each location. Basically, each doks.gate is an archway or a column equipped with several cameras and LED lights. Light barriers are integrated into the gates, which detect every material movement and then trigger a data recording. It does not matter whether forklifts, lift trucks, conveyor belts or automated warehouse vehicles are used in the warehouse.

The installed cameras take images from various angles and positions according to the signal from the light barriers. From the generated image data, the doks.gate software then generates the information that is of interest in the respective application. For example, numerous pieces of information can be read out automatically from the labels attached to the objects. Probably the most important information here is the item number or pallet ID, which can be used to uniquely assign a recorded data record including all the information recorded. The image data created by the gate can also be used as part of a photo documentation.

In the event of damage or general uncertainty about a transported object, this image data can be used to clearly trace the condition in which the goods passed through the gate and whether the corresponding damage was already present at that time. By integrating additional sensors, the doks.gate system can also determine and document the temperature, volume or dimensions of the detected objects. All data records recorded by the gate can be accessed via a digital user interface and can be easily exported to existing IT and warehouse management systems.

Since every warehouse, every process and every company has its own special characteristics and the definition of the relevant information can vary greatly from one application to the next, our doks.gates are by no means an off-the-shelf product. We plan and manufacture each gate individually in constant exchange with the future users. Users can expect an intuitively usable and innovative system that is tailored to the requirements and conditions on site.

Our solutions make warehouse management unsurpassedly simple!

doks.inventairy

The innovative drone-based solution for automated inventory in high-bay warehouses!

doks.sky

Automated system for inventory data collection and stocktaking in all outdoor block storage areas!